Experts in bespoke design and build for prefabricated modular solutions.

Barrier Group offers bespoke design and build solutions for prefabricated modular buildings projects, specialising on modularised accommodation for offshore living quarters, onshore and offshore sub-stations and other technical buildings.

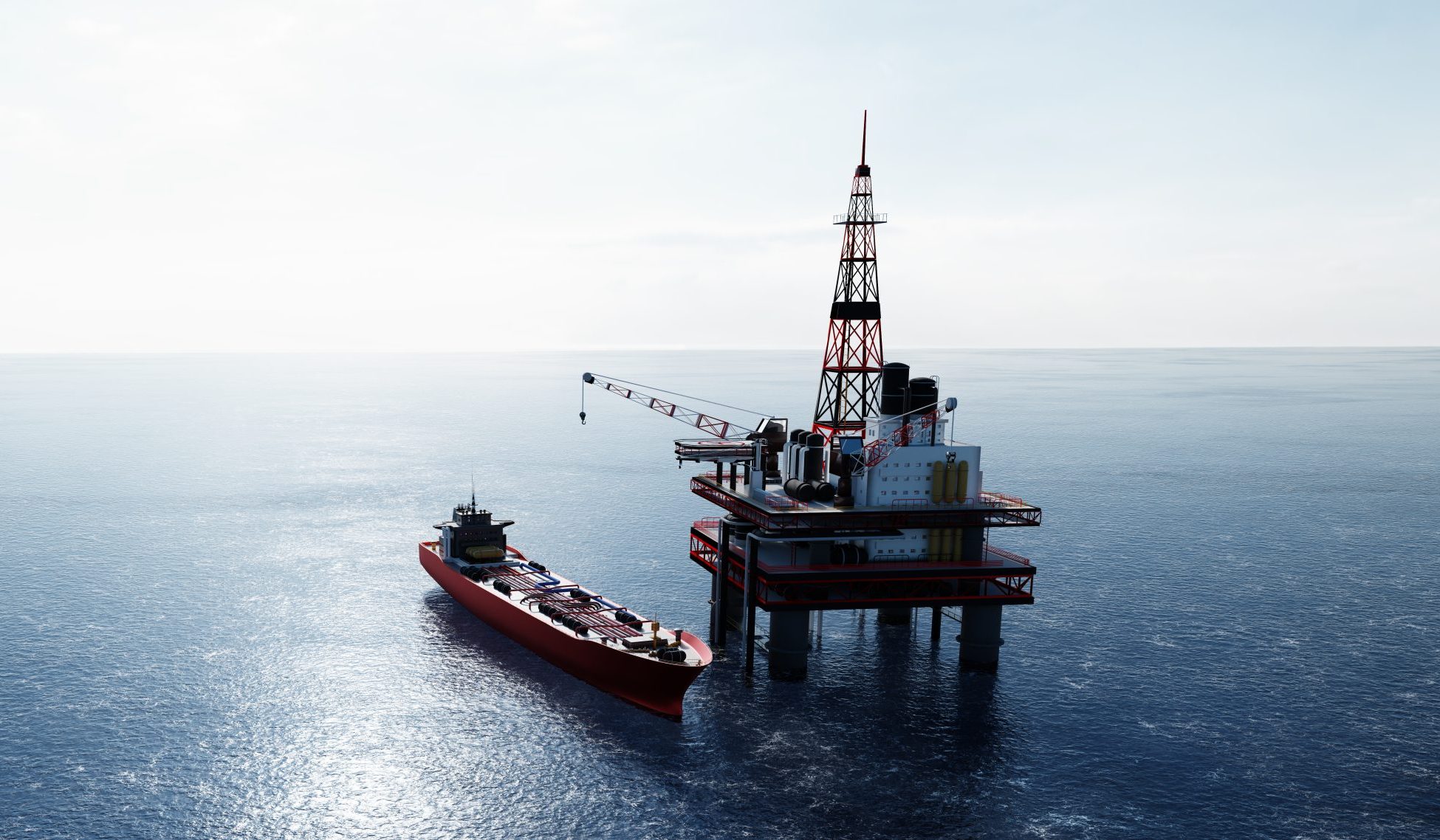

Our prefabricated accommodation modules are constructed in our dedicated quayside facilities in Teesside. Our riverside location is a huge benefit in that we have no transit restriction in terms of size of modules as we are able to deliver modules by sea as well as by road.

Design and Engineering teams are based in this location to provide hands-on field engineering during design and build phases.

Barrier undertake structural fabrication in-house or where capacity and demand dictate, procure sub-assemblies from a network of trusted suppliers where final assembly and outfitting is managed by our experienced yard construction teams.

All offshore buildings, whether living quarters, sub-stations or technical rooms, are completed to the highest standard to minimise expensive offshore hook-up and integration works. Our multi-disciplined approach mean all services are installed and pre-commissioned prior to load-out.

Barrier draw on decades of experience for the internal outfitting package and can install cabins and rooms either traditionally or by prefabrication by our architectural outfitting division.

Other services are designed and installed by in-house teams to provide full coordination of all building services to exacting project specification.

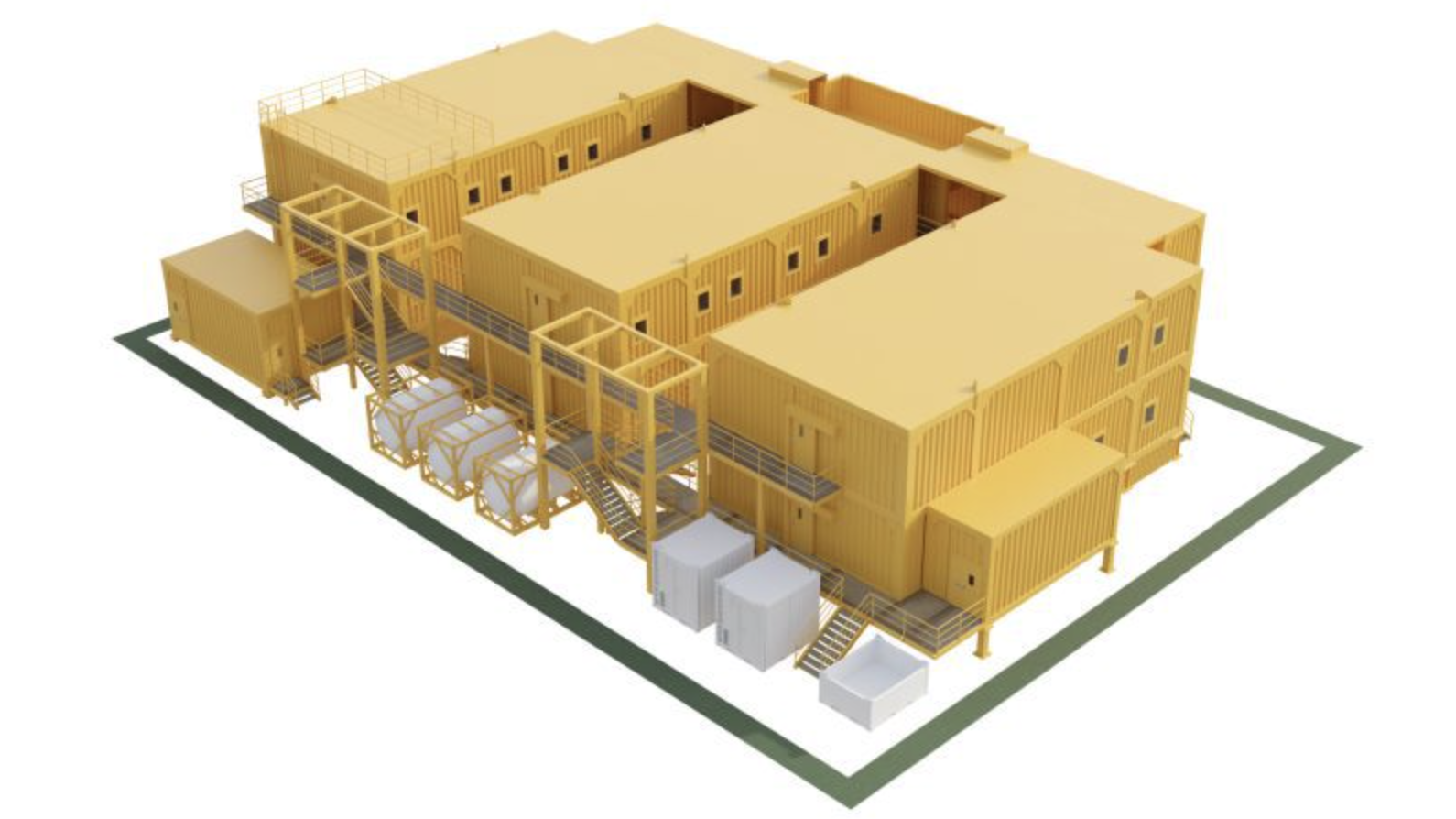

Prefabricated Onshore Technical Buildings

In a landscape where skilled resources are becoming increasingly scarce, Barrier provide offsite large, prefabricated buildings in kit form for final assembly on-site.

This concept allows for the concurrent construction of foundations, the building structure and cladding package and internal rooms and services. Barrier are able to provide design and supply of a full building managed as discrete packages, all supplied in modular kit form which provides significant schedule risk reduction to most large-scale onshore construction projects.

Additional benefits to the project include reduced site resource welfare facilities requirements, reduced material handling and laydown areas and a significant reduction in overlapping trades competing for access.

Barrier have taken years of experience gained in offshore and marine and adapted this to provide an ever-growing demand from the onshore construction industry.

Barrier are able to take basic designs for a traditionally constructed building and convert these to a fully modularised, offsite solution which significantly reduces site installation time and number of tradespeople. There are also considerable Health and Safety benefits to be realised in carrying out works off site in a more controlled manner with fewer personnel and a reduction in trade interfaces.